JK TYRE AUTHORIZED RETREADING CENTER

Cost-effective tyre life extension for commercial and fleet vehicles using JK Tyre approved retreading processes

Authorized Retreading You Can Rely On

JK Tyre Authorized Facility

Retreading operations carried out in compliance with JK Tyre approved standards, materials, and processes

Controlled Retreading Process

Each tyre undergoes structured inspection, preparation, retreading, and curing under controlled conditions

Tyre Lifecycle Optimization

Extend usable tyre life while maintaining performance, safety, and operational efficiency.

Quality & Process Compliance

Multiple quality checks ensure retreaded tyres meet defined performance and safety benchmarks

Our JK Approved Retreading Process

A structured four-stage retreading process designed to extend tyre life without compromising safety or performance

STEP 1

Inspection

Each tyre casing undergoes detailed inspection to assess structural integrity, suitability for retreading, and compliance with JK Tyre guidelines

STEP 2

buffing

The worn tread is precisely buffed to prepare the casing surface for accurate bonding and uniform retread

STEP 3

building

New tread material is applied using JK Tyre approved materials and building techniques to ensure durability and performance

STEP 4

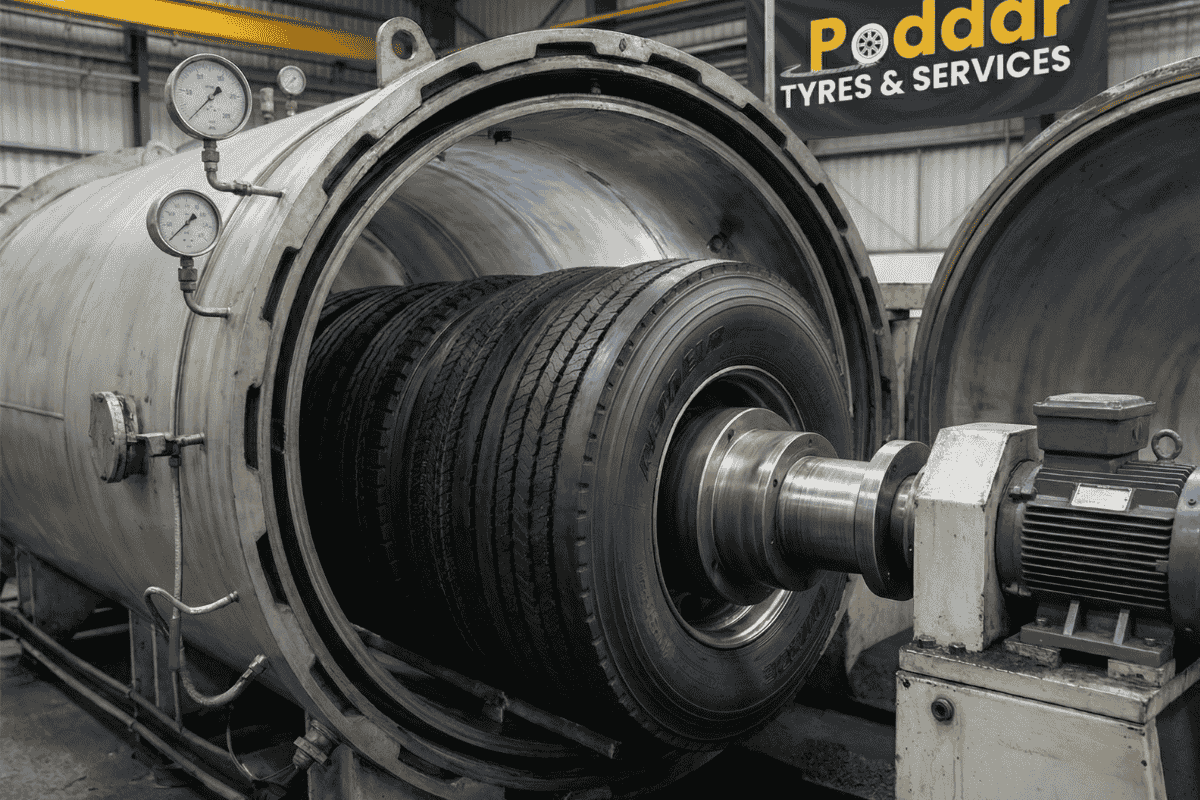

curing

The retreaded tyre is cured under controlled temperature and pressure to achieve optimal bonding and long-term reliability

Why JK approved Retreading Makes Business Sense

A practical solution for fleet operators and commercial vehicle owners focused on efficiency and value

-

Lower Operating Costs

Reduce tyre replacement expenses while maintaining reliable performance

-

Extended Tyre Lifecycle

Maximize usable life of commercial tyres through approved retreading

-

Minimized Downtime

Structured processes help keep vehicles on the road longer

-

Sustainable Choice

Supports environmental responsibility by reducing tyre waste

Vehicles Suitable for JK Retreading

Designed for commercial and fleet operations where tyre lifecycle optimization is critical

Buses & Institutional Transport

Public and private buses requiring reliable tyre lifecycle optimization.

Heavy Commercial Trucks

Long-haul and regional transport trucks operating under high load conditions

frequently asked questions

At our JK Retread Center in Poddar Motor Complex, Nirgundi, every casing is checked using JK Tyre casing inspection standards and approved equipment before retreading starts.

Only structurally sound, safe casings are accepted for retreading; damaged or unsafe tyres are rejected to protect your vehicle and load.

The biggest benefit is saving tyre cost—a quality retread usually costs only 30–40% of a new tyre while still delivering strong mileage and low cost per km for fleets.

By reusing the casing, you convert more of your original tyre investment into extra life, reduce waste and support more sustainable operations on routes around Cuttack and Odisha.

Most commercial vehicle tyres can be retreaded 1–2 times, depending on casing health, operating conditions and maintenance history.

Our team inspects each casing at Nirgundi and confirms whether it is suitable for the first or second retread before you commit to the job.

We follow the JK Tyre‑approved cold (precure) retread process, where a precured tread is bonded to the buffed casing under controlled temperature and pressure.

This precure method helps protect casing strength, improves mileage and is ideal for modern radial truck and bus tyres running on NH‑16 and other long‑route operations.

Typical turnaround time is 3–5 working days from casing inspection to final delivery, depending on workload, tyre size and any repairs required on the casing.

Fleet customers can plan batches so vehicles spend minimum time off the road while still getting consistent JK‑standard retreads.

Yes, retreaded tyres from our JK Retread Center come with a limited warranty as per JK Tyre policy, provided recommended loading, inflation and usage guidelines are followed.

Warranty coverage is explained at billing so you know exactly what is included for your application and routes.

Yes, we provide services to all major branded tyres at our Nirgundi, Manguli retread facility as long as they pass JK casing inspection and meet safety standards.

Once approved, they are retreaded using the same JK precure process to deliver reliable performance and cost savings.

Retreading typically costs only 30–40% of a new premium tyre, yet can deliver 50–90% of new‑tyre life when managed correctly, giving excellent cost per kilometre for trucks and buses.

For fleets running on NH‑16 and regional routes in Odisha, this means lower tyre budget, better return on each casing and more predictable tyre expenses.

Casings with sidewall cuts, bead damage, exposed steel belts, deep shoulder separations or major impact injuries are not accepted for retreading at our JK Retread Center.

These defects compromise tyre safety and performance, so such tyres are recommended for scrap instead of retread.

Yes, our team at Poddar Motor Complex offers post‑service support, including inflation and load recommendations, rotation advice and inspection tips to help you get maximum mileage from retreaded tyres.

We can also work with fleet owners to design tyre maintenance schedules that reduce irregular wear and improve cost per km across the whole fleet.

Not sure about the perfect solution for you?

Send your enquiry

Share your basic details and we will connect with you to explore mutual alignment and next steps. (Your information will be kept confidential and used only for communication purpose)

Poddar Tyres & Services – JK Retread Center

📍 Address

Poddar Motor Complex, NH 16, Nirgundi, Manguli

Cuttack – 754025

🕒 Service Hours

Monday to Saturday: 9:30 AM – 6:30 PM

Sunday: Closed (or as applicable)

📞 Contact

+91 8895110090

sales@poddartyre.com